search

Menu

- Chemistry

- Chemical HandlingsUnrivaled protection inside and outside the laboratory

- Filtering chemical fume hoods

- Erlab secure weighing station

- Chemical StorageYour products close at hand free of pollution and odor

- Filtering storage cabinets

- Filtration boxes

- Protecting ApplicationsWork safely, protected from pollution and dust

- Fume hoods to ensure a clean work environment

- Integration kits for exhaust hoodsNo more energy-inefficient and polluting systems

- Erlab GreenFumeHood 3 technology

- Biology

- Handling ProtectionA complete range of laminar flow devices for the secure handling of very sensitive substances

- Horizontal Laminar AirFlow Cabinet

- Vertical Laminar AirFlow Cabinet

- PCR-UV Workstations

- Laminar Air Flow Modules

- Operator ProtectionProtect yourself from pathogens with our laminar flow devices, suitable for medical or industrial environments

- Class II biological Safety cabinet

- Class II Safety Cabinets for liquid handling or cytometry applications

- Class II Safety Cabinet for Binocular and Microscope

- Absolute ProtectionPerform manipulations in a totally secure environment

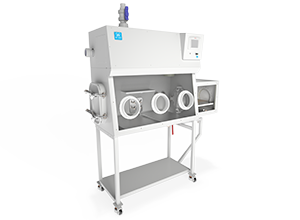

- Isolators for industrial and pharmaceutical applications

- Portable Isolation Enclosures

- Animals researchA range of equipment for animals research laboratories (for mice, rats, and poultry)

- Class II Safety Cabinet and changing station

- Vented Animal Cabinet

- Class II Biological Transfer Cabinets

- Isolators for Laboratory Animal Research

- Air quality

- Ambient Air DepollutionVersatile, molecular and particulate purification for impeccable air.

- Air purification station Halo 25 Bifiltration

- Targeted Air DepollutionTargeted, molecular or particulate purification for optimal air quality.

- Air purification station Halo 35 C Smart

- Air purification station Halo 35 P Smart

- Pollution DetectionDetect, purify and control the quality of the ambient air

- Erlab Air quality sensor

- Maintenance

- Technologies

- Ressources

- News

- Quote request

- EN

© Erlab Made by Pixels Ingénierie